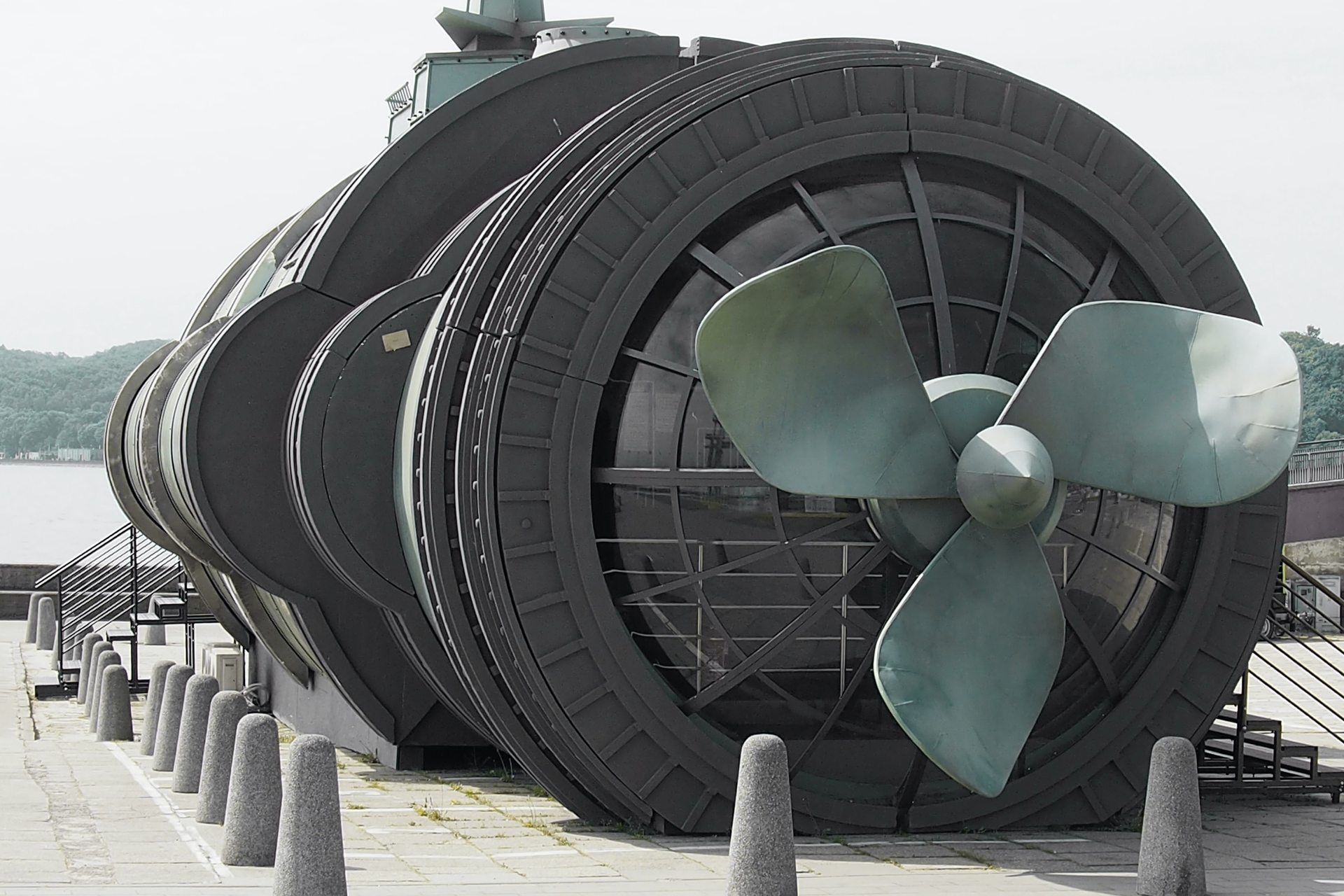

Naval Equipment

The harsh over-and-under-the sea environments have an impact on the condition and integrity of vessels, marine equipment, electronic equipment, and even onboard weapons in naval ships.

Intense weather conditions, humidity levels, salt and harsh operations are all factors that contribute to damaging the structural integrity of naval equipment by generating faults and damage such as corrosion of metal parts, leading to further operations technical issues.

These forms of faults and damage occur gradually and may be difficult to spot timely and visually and repair without extensive costs and off-hire downtime.

We are solution providers on a wide range of maritime industry issues concerning the structural integrity and maintenance of naval vessels and equipment.

Our solutions, tailored to the maritime assets include:

- Vessel damage and repair management

- Risk Based Inspection [RBI]

- Tank Inspection

- Piping Inspection

- Weld Integrity Assessment

- Marine corrosion testing and monitoring

- Structural integrity assessment of ship hulls

- Ship and yacht floor inspection

We have extensive hands-on experience in the successful management and delivery of the entire inspection and testing fields. We can utilise inspection teams, rope access teams, scaffolders, blasters, coating painters and welders. We ensure all works are carried out properly, to meet engineering and standards requirements.

There are well-established Non-Destructive Testing [NDT] methods employed in the maritime industry – all of which make naval vessels and equipment inspection and maintenance reliable and compliant. These are nowadays complemented by high-tech –yet proven– technological alternatives that allow faster and more productive mapping of naval equipment issues in an economical and non-intrusive manner.

These technologies and methods include, but are not limited to:

- Phased Array Ultrasonic Testing [PAUT]

- Time-of-Flight Diffraction [TοFD]

- Total Focusing Method [TFM]

- Computed Radiography [CR]

- Magnetic Flux Leakage [MFL]

- Visual Testing [VT]

- Penetrant Testing [PT]

- Magnetic Particle Testing [MT]

- Ultrasonic Testing [UT]

- Radiographic Testing [RT]

- Eddy Current Testing [ET]

- Leak Testing [LT]

- Heat Treatment

- Materials Mechanical Properties

- Thermography