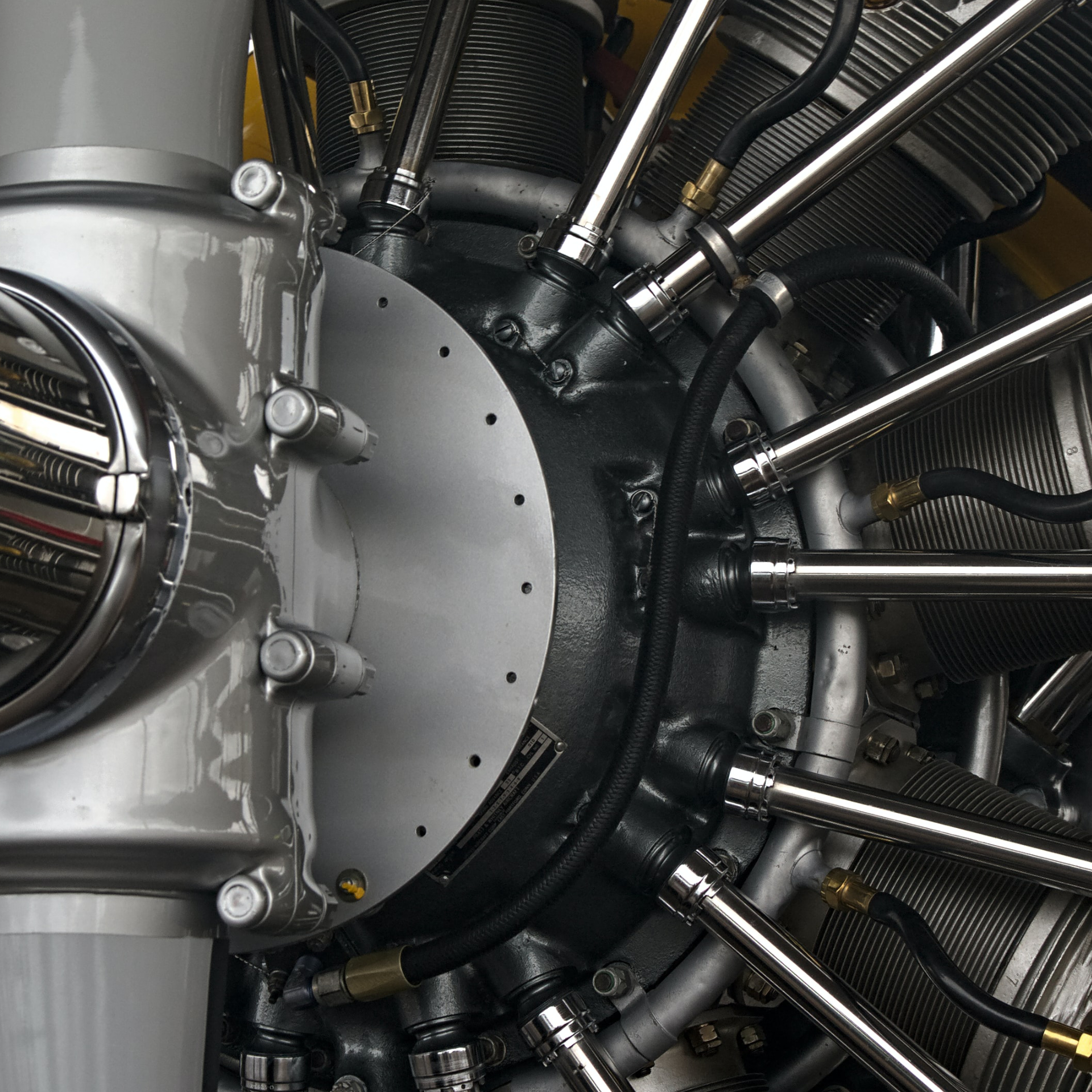

Rotating Equipment

At the heart of many Oil, Gas and Process industries is the critical Rotating Equipment. It is very important that this is correctly specified, designed, operated, and maintained.

With Rotating Equipment, the ultimate objective is to maximise the reliability and output from the machinery as well as the production process, whilst minimising required maintenance and driving down the total life cycle cost.

Rotating Equipment is often managed separately from Fixed Equipment because it has different design, maintenance, and inspection requirements. Our engineering experts know all the differences and can offer generic and custom solutions to troubleshoot any mechanical failures and avoid unplanned downtime.

The key services tailored to Rotating Equipment include:

- Rotating Equipment Troubleshooting

- Predictive, Preventive and Corrective maintenance

- Failure Investigation & Analysis

- Root Cause Failure Analysis [RCFA]

- Condition Monitoring

- Machinery Design Study Reviews

- Machinery Specification Development

- Machinery Overhaul Supervision and Field Services

- Factory Acceptance & Performance Testing

- Repair Consulting & Supervision

- Rotational Equipment Turnaround Planning

- Rotating Equipment Maintenance Audits

Whether you want to solve a specific Rotating Equipment problem, run a regular equipment inspection, or improve your overall maintenance strategy and efficiency, Newtron is your partner.

We can avoid unplanned downtime by detecting and proactively diagnosing impending machine failures, through Condition Monitoring and data visualisation. Operational and maintenance issues are tackled with Non-Destructive Testing applied methods.

Technologies we use to solve related technical issues are: