Materials Engineering & Corrosion Protection

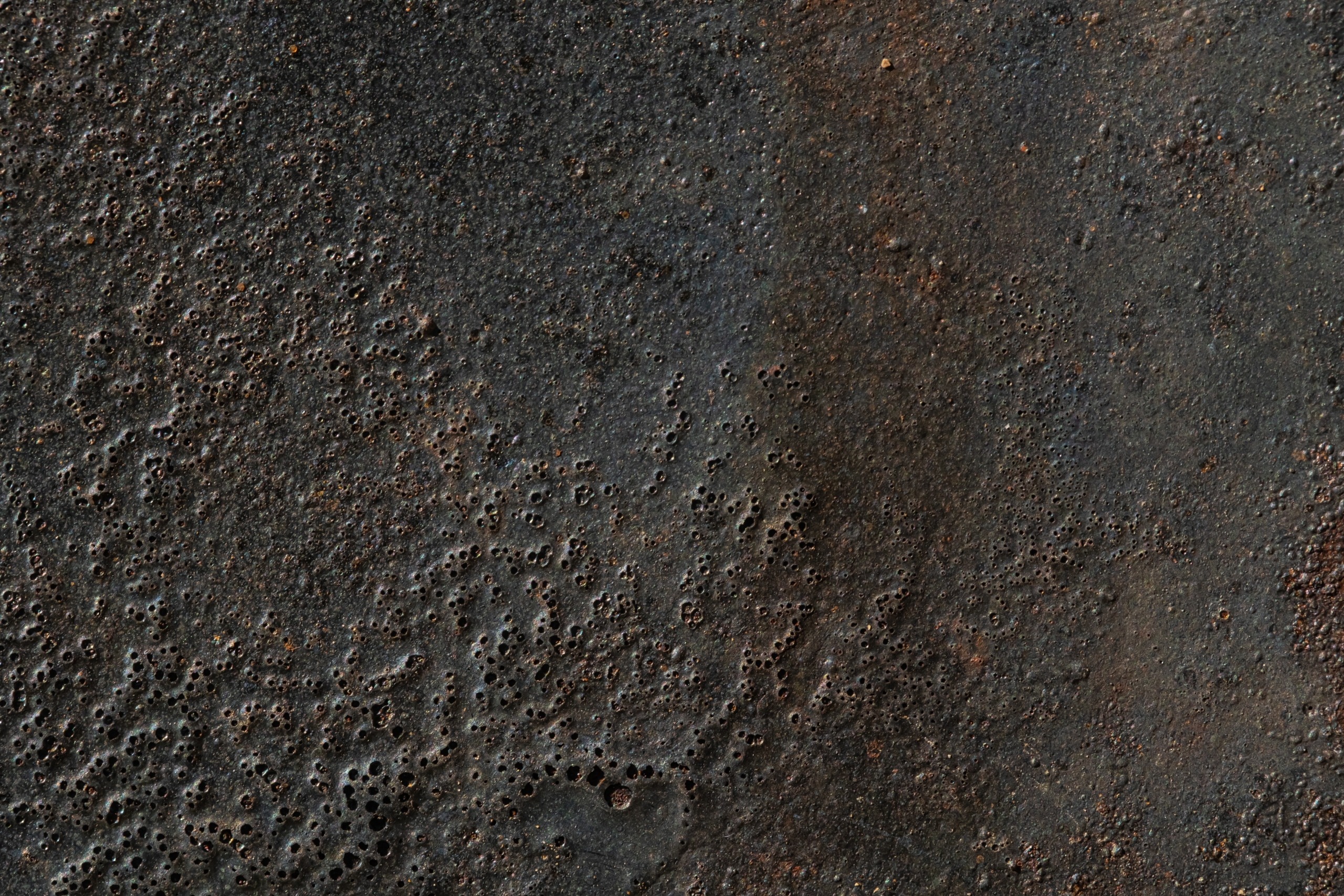

Corrosion is the degradation of materials’ properties due to interactions with their environments and corrosion of most metals (and other materials for that matter) is inevitable, leading to assets’ operational failures and high repair and maintenance costs. However, in many cases, corrosion may be predicted, managed, mitigated or prevented entirely by the selection of correct materials, the inspection of conditions and continuous monitoring.

Our materials and corrosion specialists are knowledgeable and experienced in materials properties and their behaviour in corrosion conditions. They know corrosion mitigation methods, corrosion monitoring techniques, and their impact on equipment and piping systems.

In Newtron, we also rely on the employment of technologies such as NDT, Materials Mechanical Properties and Heat Treatment to implement a range of corrosion-related services. From Consulting Engineering in materials selection to Corrosion Inspection programs, facilitation of RBI and FFS assessments, Coatings works, Cathodic Protection services or Internal Corrosion Monitoring, to name a few, we can cover all your needs in corrosion management.

Maintaining asset integrity translates into asset lifecycle longevity and a continuous stream of revenues.

Corrosion is one of the most problematic issues in many industries and often leads to significant issues such as disrupted operations and unplanned maintenance costs. It is essential to prevent, manage and continuously monitor corrosion to avoid equipment failure, asset degradation, delays, shutdowns, accidents and incidents that could result in loss of life, profits and reputation.

Industries that can benefit from Materials & Corrosion solutions include: