Materials Mechanical Properties Testing

Materials mechanical properties testing is a critical step in understanding how your materials will perform or react under a wide variety of stresses. We can assist you in evaluating and understanding your material’s properties, from tensile strength to thermal analysis and beyond with a broad range of material mechanical properties testing services, specialising in metals, advanced composites, polymers, ceramic composites, and many more in projects large and small.

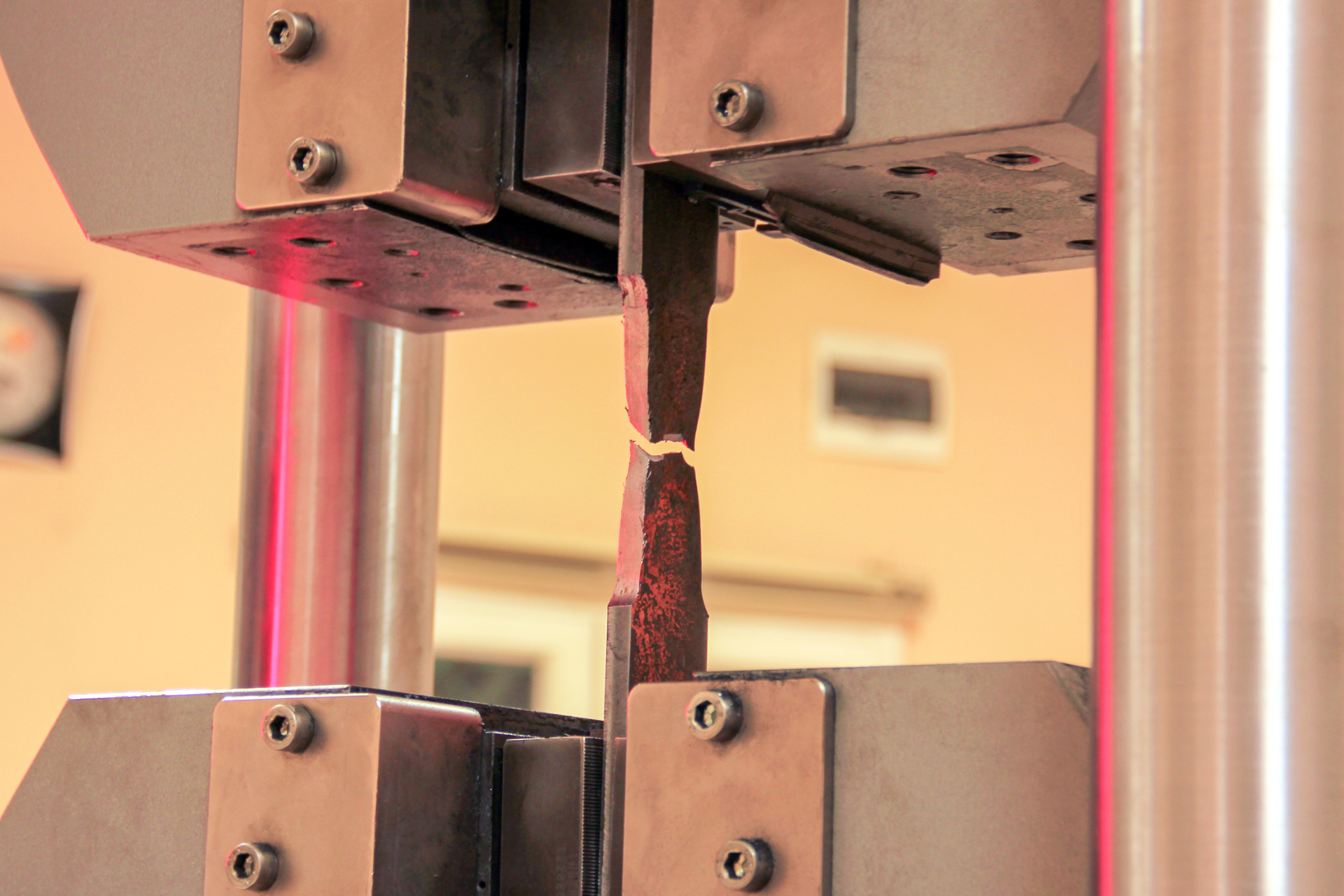

The key principle of materials testing is the mechanical loading of a specimen or material up to a certain deformation or to break. The material properties, which come as a result of this, are shown through material characteristics.

There are several test methods which can be applied in materials testing:

- Tensile Testing

- Bend Testing

- Impact Testing

- Hardness Testing

- Macroscopic Testing

- Replica Testing

Newtron Technologies provides a comprehensive range of Materials Properties Testing and analysis that supports industrial, and military clients among others.

The following test methods cover procedures, definitions and specifications for the materials mechanical properties testing of steels, stainless steels, and related alloys. They are used to determine properties required in the product specifications. Standard methods of testing are to be followed to obtain reproducible and comparable results. Here are the most commonly followed organisations in the world for creating Materials mechanical testing standards and codes:

This information is a collection of references. While we have made every attempt to ensure that information on this site is updated, Newtron is not responsible for any errors or omissions, or for the results obtained from the use of this information. It is not guaranteed to be complete, correct, current, or up to date and may be changed without prior notice.